Z-AXIS FIBER

First-of-a-kind advanced materials are conductive and durable like metal, yet light like plastic

Created entirely from reclaimed carbon fiber, allowing for high-performance, high-volume materials and components with the lowest possible carbon footprint

Created entirely from reclaimed carbon fiber, allowing for high-performance, high-volume materials and components with the lowest possible carbon footprint

Markets & Applications

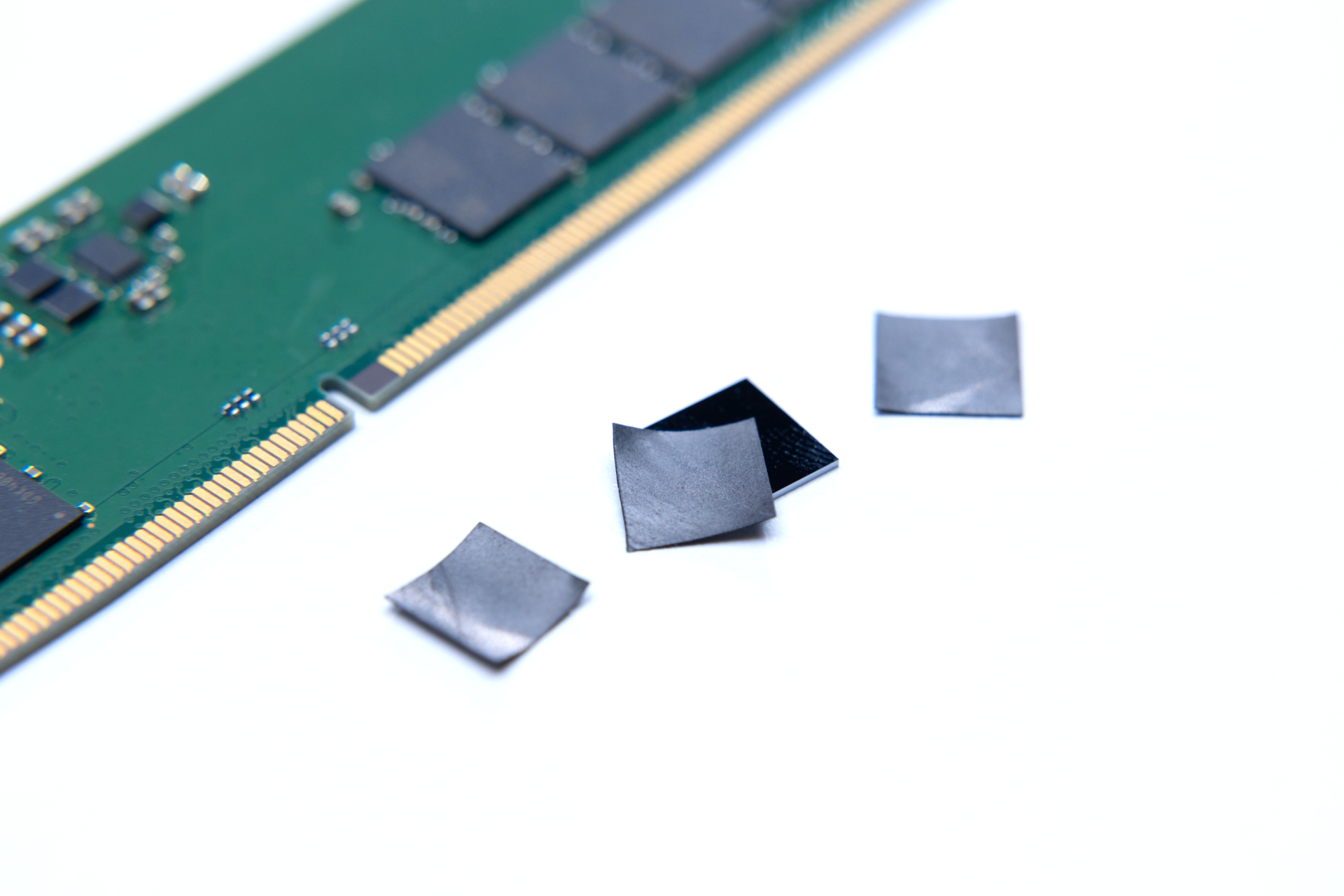

SEMICONDUCTORS

HOT AI RACE NEEDS COOL CHIPS

Lightweight, high performance TIMs

Increased cooling for discrete power packages

Thermal Interface Materials with low thermal resistance

Increased cooling for discrete power packages

Thermal Interface Materials with low thermal resistance

ELECTRIFIED VEHICLES

JOURNEY TO 100% ELECTRIFICATION

Lightweight, no-corrosion bipolar plates

60% weight reduction vs. stainless steel

Thin (<0.2mm) polymer composite bipolar plates with high electrical conductivity

60% weight reduction vs. stainless steel

Thin (<0.2mm) polymer composite bipolar plates with high electrical conductivity

SAFETY

ENHANCED BALLISTIC PROTECTION

Energy-absorbing materials for mass-produced composite armor

Significant reduction in trauma from back face deformation

30% lower plastic deformation vs current systems

Significant reduction in trauma from back face deformation

30% lower plastic deformation vs current systems

AEROSPACE

SKY-HIGH EXPECTATIONS FOR AIRPLANES

Materials to protect spacecraft during atmospheric re-entry (2,500°C+)

30% increase in interlaminar shear strength properties for conventional ceramic matrix composites

Commercial partnership with Textron (NYSE: TXT)

30% increase in interlaminar shear strength properties for conventional ceramic matrix composites

Commercial partnership with Textron (NYSE: TXT)

Proven, Scaled Manufacturing

How can we help you today?