Products

Powered by our patented Z-axis Fiber technology

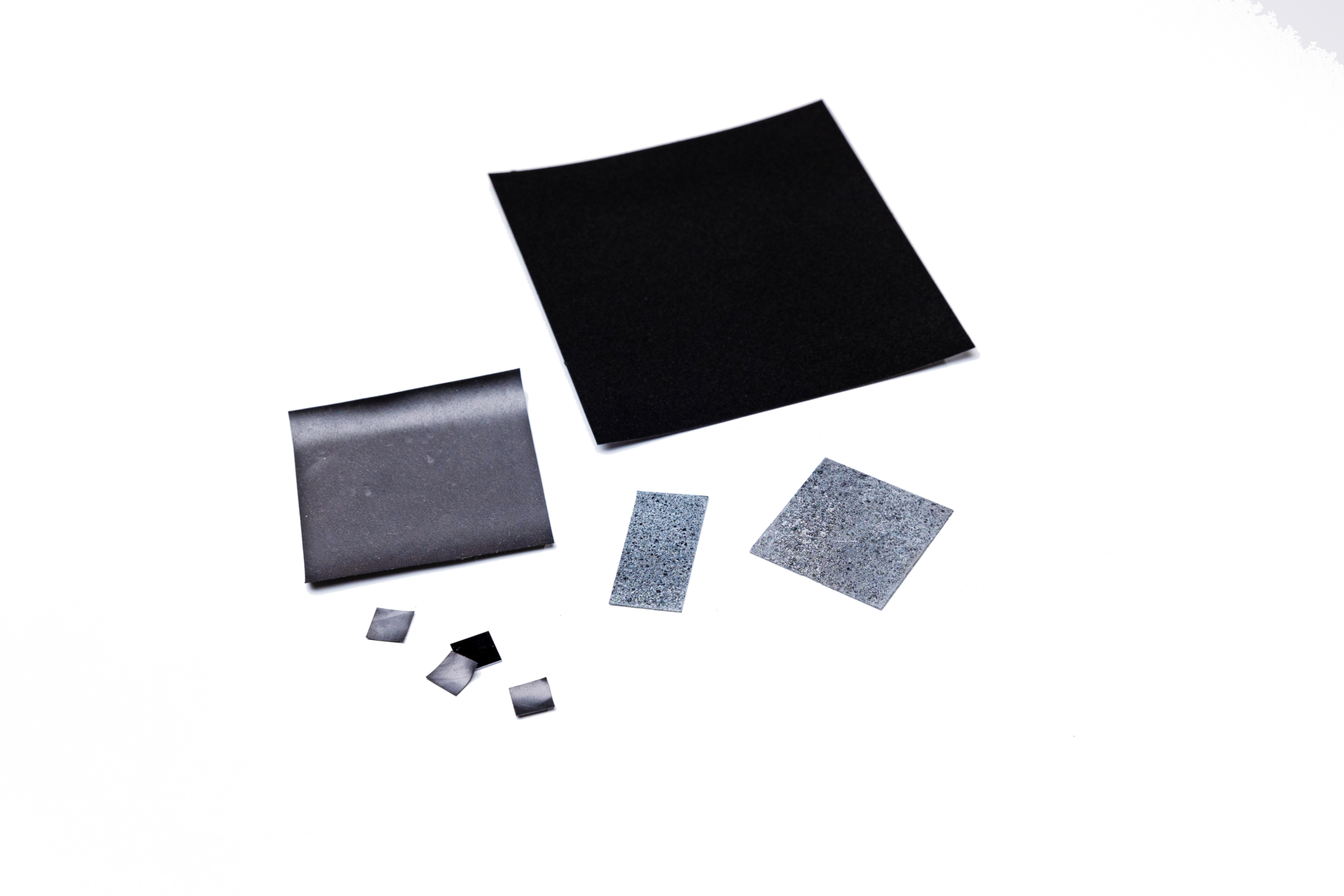

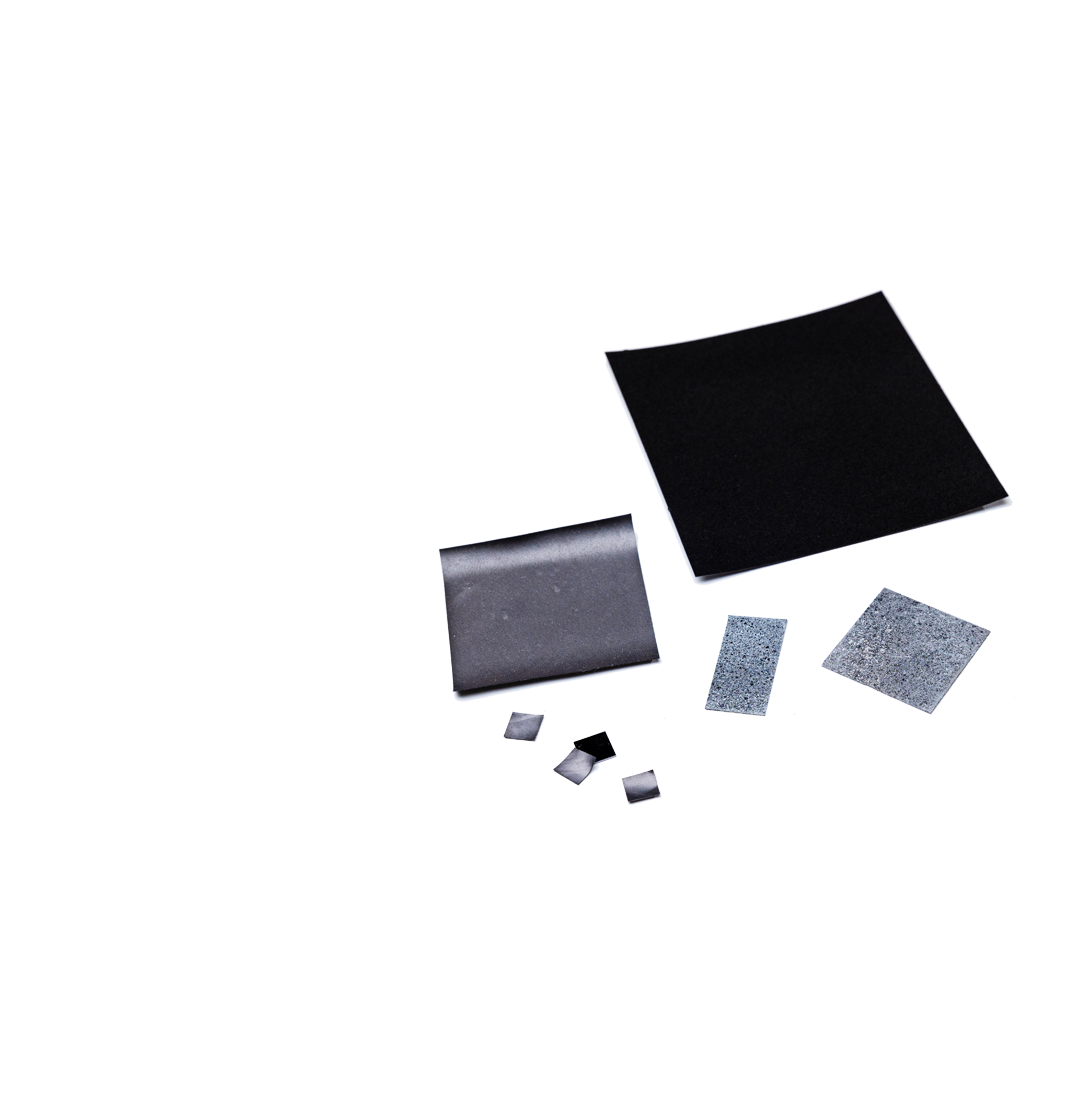

ZRT Thermal Interface Materials

Solving Efficiency Losses of Thermal Interfaces

- Solving the performance and reliability issues of semiconductors for computing, telecom, and power applications

- Z-axis Fiber Polymer TIM:

- 20 to 50 W/m-K conductivity

- Zipper-like effect eliminates delamination

- Z-axis Fiber Solder & Liquid Metal TIM:

- 150 W/m-K thermal conductivity

- Sponge-like effect eliminates pump out, especially with liquid metal

- Proven and highly scaled manufacturing process (1,000,000 m2/yr capacity)

- Does not contain nanomaterials, which are very expensive and hard-to-scale

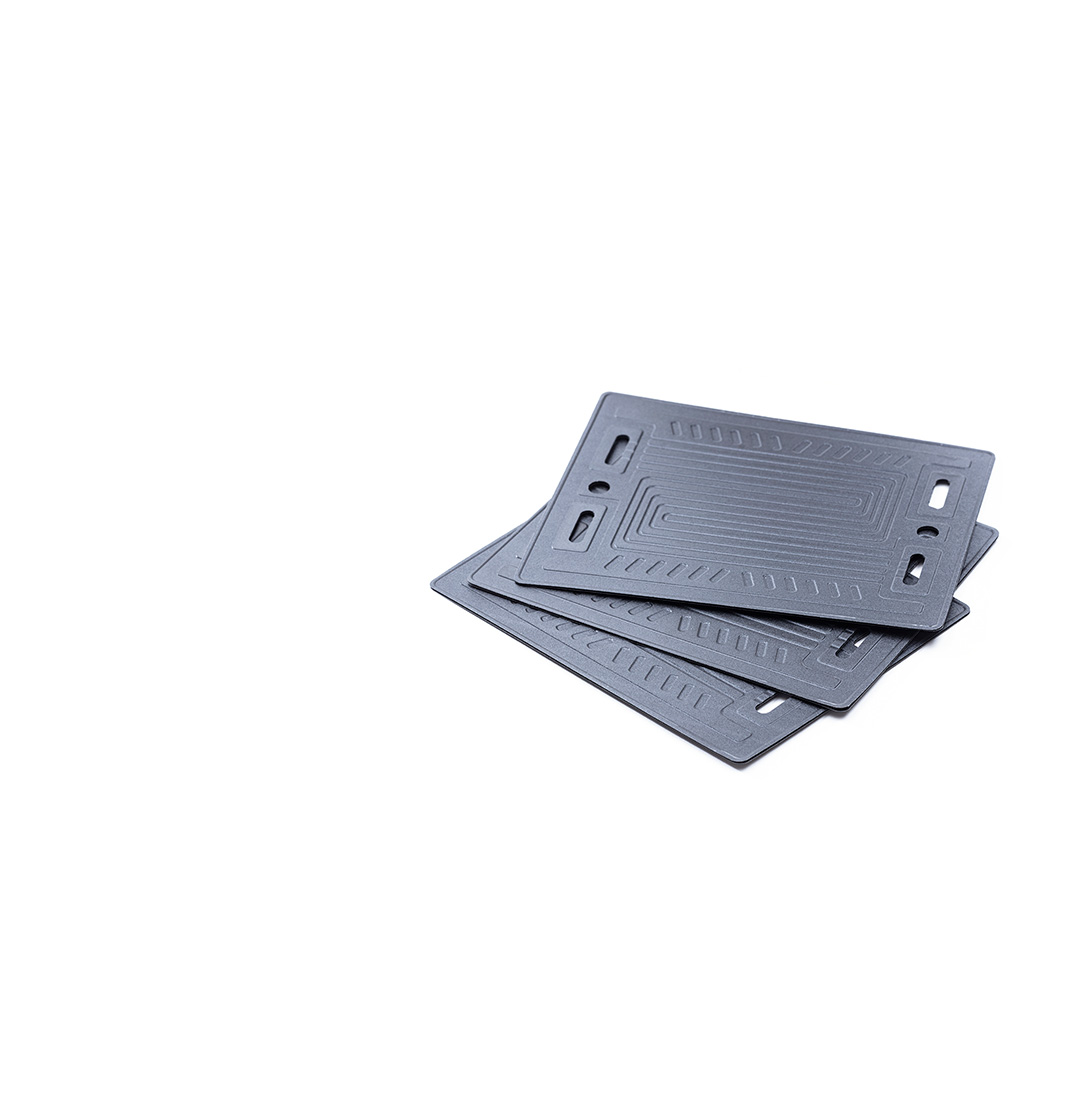

Bipolar Plates

Fuel cell bipolar plates (BPPs) made with thermoformed ZRT films

- 60% lighter than stainless steel BPPs, corrosion-inhibiting coatings not required

- Manufactured with high-rate plastic film thermoforming processes

- Thin-walled BPPs (<0.2mm) while maintaining low areal specific resistance and low gas permeability

HOW CAN WE HELP YOU TODAY?